TP-44

May 28, 2024

MP-235

May 28, 2024Thermoplastic solvent-based acrylic resin for the production of plastic parts coating

Main propertiesFilm propertiesConsumption guideSuggested use casesStorage conditionsTechnical information

| appearance | Clear liquid | ||||

| Type of polymer | No cross-linking | ||||

| Solvent | Xylene | ||||

| Solubility | Soluble in: esters, ketones, some aromatic hydrocarbons, some glycol ethers | ||||

| Insoluble in: alcohols and some glycols | |||||

| Color |

|

||||

| Solid Percentage (ASTM D-1259) | 1 ∓ 45 | ||||

| Acid Number (mg KOH/g) (ASTM D-1639) | <10 | ||||

| (°C) Tg | 106+ | ||||

| Viscosity in (cP) 25°C (ASTM D-562) | 3000-7000 | ||||

| Density in (g/ml) 25°C (ASTM D-1475) | 0.98 | ||||

| ignition point (°C) (ASTM D-93) | 24 |

Very fast drying and excellent adhesion on some plastics, good hardness and scratch resistance, resistant to moisture and thermal changes, resistant to alcohol solvents and hydrocarbons.

Dry for 30 minutes at 50 degrees Celsius or ambient temperature. For additional information, refer to the suggested formulas

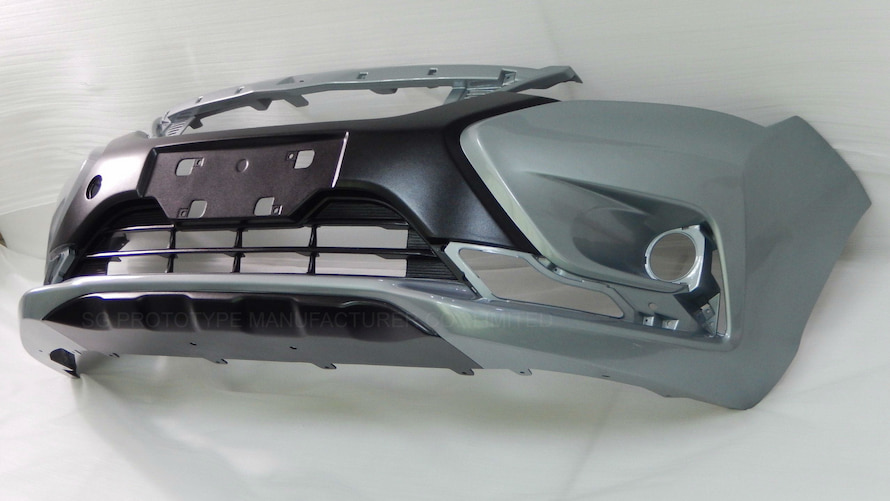

Making the cover of all types of plastic substrates such as PC, NORYL, HIPS, ABS, PVC, which are used in the manufacture of home and office electrical appliances..

Store in a closed container in a covered place for up to 24 months. Regardless of any change in properties, sometimes this resin is a veil